The Future of D2C E-commerce: How to Optimize Supply Chains & Pricing

Overview

The direct-to-consumer (D2C) business model is transforming the retail landscape. Brands that sell directly to customers have gained enormous traction due to their control over customer relationships, product personalization, and bypassing traditional middlemen. However, this competitive edge comes with challenges. Consumers now demand faster shipping, sustainable practices, and dynamic pricing—all while retaining their trust and loyalty.

According to eMarketer, D2C e-commerce sales in the U.S. are projected to surpass $213 billion by the end of 2024, accounting for a significant portion of total online revenue.

Despite this growth, rising customer acquisition costs and increasing consumer expectations put brands under rising pressure to optimize supply chains and pricing strategies.

In this blog, we’ll discuss actionable methods to future-proof your D2C operations and thrive in 2025’s competitive landscape.

Ready to Stay Ahead in the Competitive D2C Landscape?

Explore how we can empower your D2C brand to thrive in 2025 and beyond!

Book a Demo Today

Table of Contents

- Revolutionizing D2C Supply Chains

- Hyper-Personalized Fulfillment

- Sustainability-Driven Strategies

- Embracing Automation and Robotics

- The Rise of Micro-Fulfillment Centers

- The New Age of Dynamic Pricing

- How to Align Supply Chains and Pricing

- Implementation Roadmap

Revolutionizing D2C Supply Chains

From Linear to Networked Supply Chains

Gone are the days of traditional linear models where products travel from the manufacturer to a central warehouse and then to the customer. Modern D2C brands are embracing networked supply chains to reduce inefficiencies, avoid delays, and meet increasing demands.

Key Features of a Networked Supply Chain

Distributed Fulfillment Nodes:

By establishing micro-fulfillment centers near major markets, D2C companies such as Glossier have achieved 24% faster deliveries and significantly reduced shipping costs by 17%.

Omnichannel Visibility:

Brands like Warby Parker utilize real-time centralized inventory systems to enable fewer stockouts, lower inventory holding costs, and better order prioritization.

IoT and Blockchain Integration:

Internet of Things (IoT) sensors are transforming real-time tracking of inventory and delivery, while blockchain technologies ensure greater supply chain transparency and accountability.

Hyper-Personalized Fulfillment

The Rise of Customized Fulfillment Experiences

With 71% of consumers now expecting personalized shopping experiences from their favorite brands, fulfillment is becoming the next battleground for personalization (McKinsey). Customers aren’t just looking for products they want tailored delivery and unboxing experiences.

Strategies:

AI-Driven Personalization: Predictive models can analyze purchase behavior to recommend products and delivery preferences.

Custom Unboxing: Think personalized thank-you cards, unique packaging designs, and eco-friendly reusable boxes.

Delivery Choice Flexibility: Allow customers to choose preferred carriers, delivery times, and even specific “green” shipping options.

Sustainability-Driven Strategies

Consumers are increasingly aligning their purchase decisions with brands that adopt environmentally responsible practices. According to an IBM Institute report, 88% of global buyers are more likely to remain loyal to brands that support eco-conscious efforts (IBM Study).

Environmental Priorities for D2C Brands

Eco-Friendly Packaging: Only 14% of plastic packaging worldwide is recycled (World Economic Forum). D2C companies should invest in biodegradable or reusable packaging.

Carbon-Neutral Logistics: Partner with green shipping carriers and adopt efficient delivery routes to reduce emissions.

Circular Supply Chains: Incorporate returns, refurbishment, and recycling programs into your fulfillment process to minimize waste.

Embracing Automation and Robotics

To meet ever-growing demands for same-day and next-day delivery, automation has become the cornerstone of modern D2C fulfillment centers. The warehouse automation industry is expected to reach $41 billion by 2027, according to Fortune Business Insights (Source).

Example Solutions:

Automated Guided Vehicles (AGVs) for optimized inventory movement.

Robotic Picking Systems that improve order accuracy by 99%.

AI-Powered Inventory Tools for real-time demand forecasting and restocking optimization.

The Rise of Micro-Fulfillment Centers

Located closer to urban hubs, micro-fulfillment centers (MFCs) enable faster last-mile delivery at reduced costs.

How You Can Leverage MFCs:

Localized Warehousing: Ensure that most high-demand products are stocked near key market areas.

Environmental Benefits: Use electric vehicles (EVs) for last-mile delivery when operating from nearby hubs.

Retail Partnerships: Collaborate with brands for shared fulfillment spaces to reduce capital expenditure.

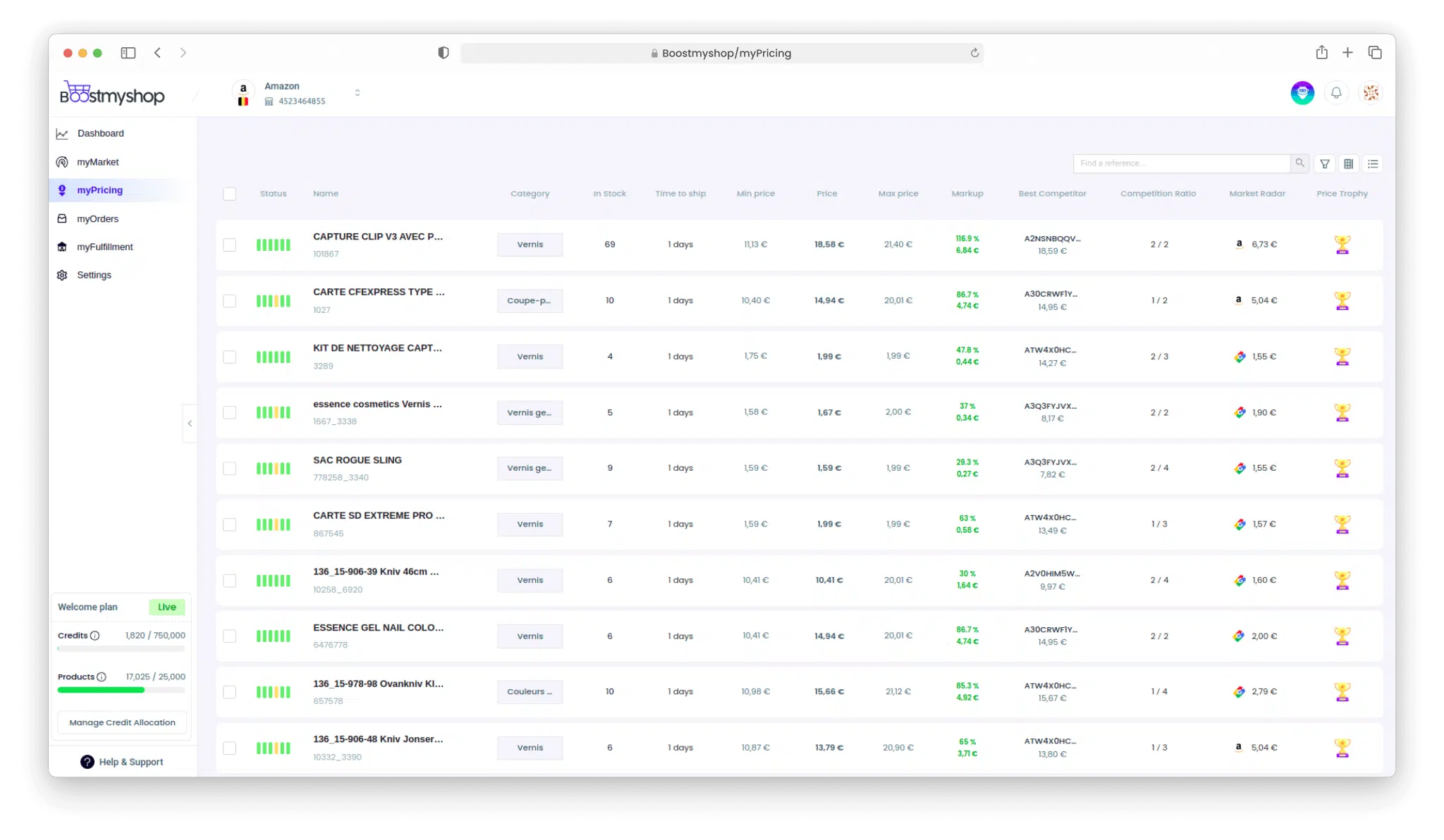

The New Age of Dynamic Pricing

Moving Beyond Cost-Plus

Old cost-plus models are giving way to smarter strategies. Pricing needs to consider real-time competitor activity, seasonality, and even regional customer demand.

Must-Have Features of a Dynamic Pricing Strategy:

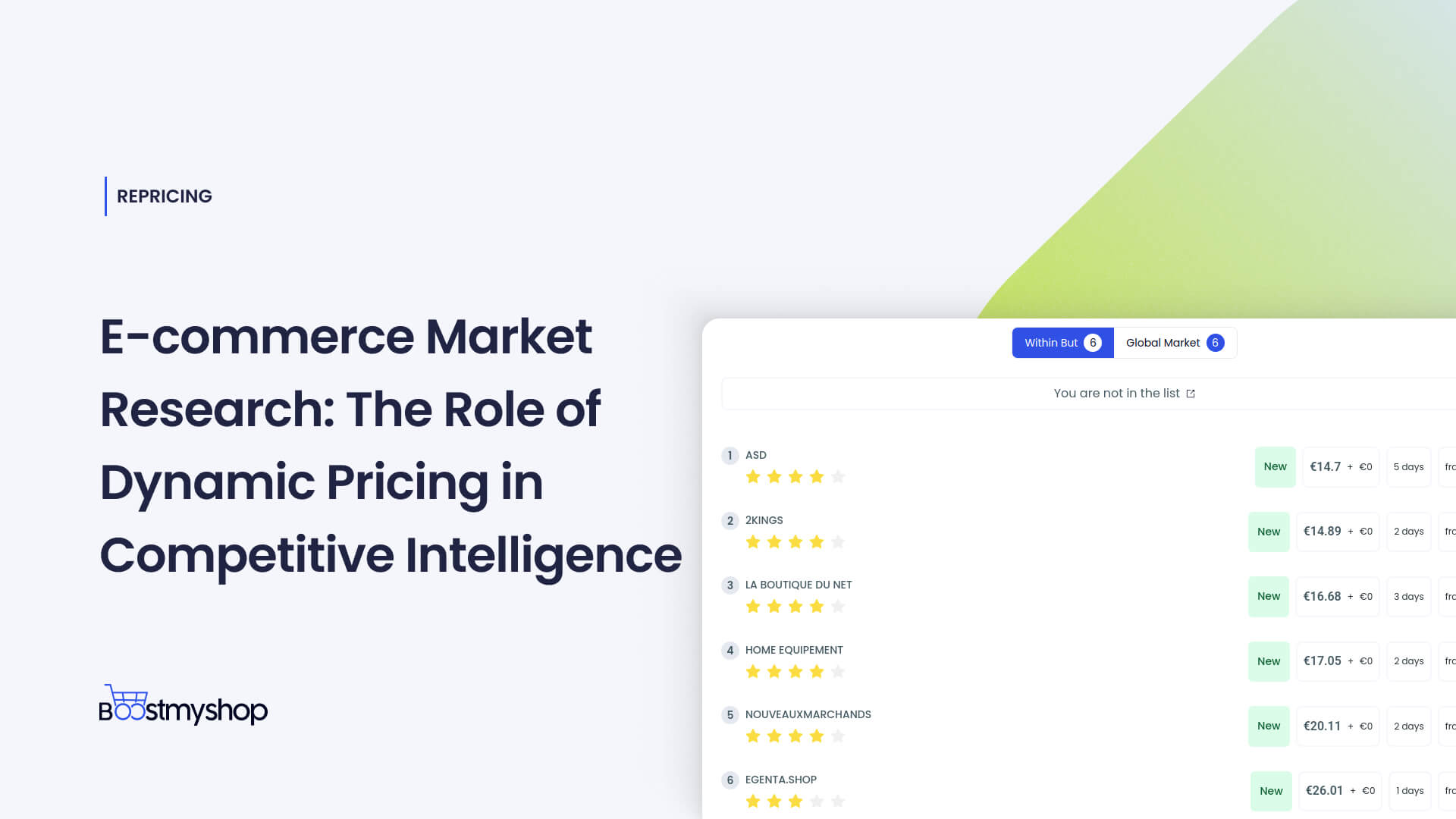

Competitor Monitoring: Tools like myPricing help track real-time pricing across categories.

Geo-Based Adjustments: Charge appropriate premiums or offer discounts based on shipping location.

Machine Learning Algorithms: Predict optimal prices based on buying patterns.

Stat: BigCommerce highlights that 82% of online buyers compare prices across stores before checkout (Source).

How to Align Supply Chains and Pricing

Why Integration Matters:

The disconnect between supply chain operations and pricing strategies results in inefficiencies, overstocking, or missed revenue opportunities.

Action Plan:

Inventory-Tied Pricing: Avoid stockouts by adjusting prices dynamically for limited inventory.

Localized Pricing Models: Charge premium rates for express shipping zones while incentivizing eco-friendly slower delivery methods.

Synchronized Systems: Combine real-time supply visibility, customer demand data, and pricing AI for holistic decision-making.

Implementation Roadmap

Phase 1: Build the Foundation (Months 1-3)

Implement centralized inventory visibility solutions and review competitor pricing tools and analytics.

Phase 2: Implement & Test (Months 3-6)

Develop automation strategies in your warehouse and create AI-driven bundle recommendations.

Phase 3: Scale Efficiently (Months 6-12)

Expand regional MFCs for faster last-mile delivery and experiment with regional pricing variations.

Conclusion

Brands that successfully integrate supply chain efficiency with sophisticated pricing strategies will lead the D2C market by 2025. With customer demands growing every day, adoption of sustainability practices, hyper-personalization, and data-driven pricing will be the key pillars of success.

Ready to Transform Your D2C Operations?

Book a Demo with Our Experts to discover how our specialized solutions can help you optimize your supply chain and pricing strategy for maximum profitability and growth.

Book a demo