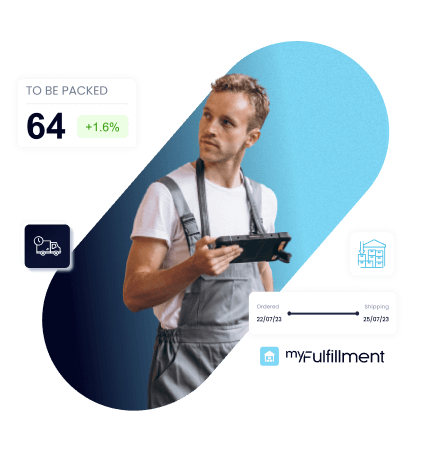

Manage supply needs with myFulfillment

Good supply needs management is a key factor in a company’s profitability. myFulfillment, our multichannel solution developed by Boostmyshop, has been designed to help you manage your e-commerce site, whether it be for order preparation or supply requirements.

What is the supply chain?

Supply for a company consists in buying products for resale. It is an integral part of stock rotation, i.e. the entry of products but also their exit. Good supply needs management will boost your profitability.

Supply requirements are a key feature of procurement, they summarise the products that the system recommends to purchase.

How do you manage your supply needs with myFulfillment?

myFulfillment has been developed to help you manage your e-commerce, including the replenishment of your products. From the replenishment screen, you have access to a list of products that myFulfillment recommends you to purchase. There are two reasons why a product may appear in this list :

- You have sold the product but do not have it in stock

- The stock of the product falls below your ideal stock level

For each product, you can see the recommended quantities to be supplied in order to dispatch customer orders, but also in order to reach your ideal stock level.

Each product has a “low stock”, “backorder” or “awaiting receipt” status:

- Low stock: you must buy the product in order to reach a minimum stock level.

- Remaining: you must purchase the product to ship a customer order.

- Awaiting receipt: there are one or more supplier orders expected that cover the requirements. Once the purchase order has been received, the product will be removed from the supply requirements screen.

How to select the quantity of products to be supplied?

You can select the quantity of each product to be added to the purchase order. myFulfillment recommends two quantities to replenish :

- A minimum quantity you need to ship customer orders

- A maximum quantity that you need to ship customer orders, plus the quantity needed to reach a minimum stock level.

In the column “quantities to order” you have 3 possibilities:

- Fill in the desired quantity manually

- Use the button to the left of the text box to select the minimum quantity recommended by myFulfillment.

- Use the button to the right of the text box to select the maximum recommended amount of myFulfilment.

How to select products from a single supplier?

You have the possibility to filter products per supplier. This means that you can select supplier X and you will then see a list of products that myFulfillment recommends you to replenish based on this supplier.

If a product is associated with one or more suppliers, the associated suppliers are displayed with the purchase price.

How do I create a purchase order?

The purpose of the replenishment requirements screen is to help you easily create a new purchase order.

First, you need to apply the filters to identify the products for the supplier for which you wish to place a purchase order :

- Using the “Supplier” column

- Using filters by product name

- Optionally, using the “Status” column (if you wish to order only the products required for backorders)

Once you have filtered the products, you must define for each product the quantity to be purchased.

Then, once you have filled in the product quantities, you can create a new purchase order using the “Create a new purchase order” button: a list of suppliers appears, click on the desired supplier and a new purchase order is created for the selected supplier, with the product and quantities required.

With myFulfillment, you save time in managing your procurement needs. So you can optimise your e-commerce logistics even further without neglecting your profitability.

Glossary

Backorder quantity: This is the quantity you need to purchase to process backorders (backorder status).

Low stock quantity: this is the quantity you need to buy to reach the ideal stock level.

Quantity to be received: this is the quantity expected from the purchase with the status “expected”. Orders with another status are not taken into account.

Suggested quantity to be ordered: this is the sum of the quantity needed for the late order + the quantity needed for a low stock, from which the quantity to be received is deducted.

Automating Stock Management

Automating Stock Management